“Our food is often contaminated by pathogens such as Salmonella, Listeria and E. coli.”

Salmonella, Listeria, E. coli. Wondering why these names sound so familiar? Unfortunately, these aren’t the names of popular celebrities, but of common pathogens that can contaminate our food. While it is true that our gut is home to around 100 trillion bacteria, these are extremely beneficial in keeping our digestive system functioning properly. Food borne pathogens on the other hand, multiply rapidly, destroying the delicate balance of the gut microbiota, causing diarrhoea and other illnesses. Whether in meat, dairy, eggs, spices, or even in farm produce, these pathogens have the ability to cause widespread contamination, as they are often resistant to both heat and cold, implying washing, refrigeration or cooking will not destroy them. Livestock naturally present a higher likelihood of contamination, however, due to the widespread use of manure and improper disposal of sewage, these contaminants have begun to emerge even in fresh produce.

Standards and practices in the food packaging industry

With growing populations to feed, it becomes more and more important to set up best practices that begin with how our produce is farmed, in order to control such outbreaks at the source. One such protocol to follow is the Hazards Analysis and Critical Control Points (HACCP), that originated in 1960, and has since become a standard in identifying hazards, assessing risk, and controlling outbreaks, in order to promote food safety. Employing the HACCP standard ensures that food is tested, and checked regularly, right from sourcing, to processing and ending with its packaging. All this is great, but this is a system that monitors and controls, but does not prevent. How can food contamination be prevented altogether?

How to prevent contamination in food

"Sterilization is a process whereby all microorganisms as well as spores are completely destroyed, thereby preventing future contamination."

Before we get to preventing contamination, it is essential to understand that bacteria and other pathogens cannot develop in the absence of contamination, however minute. This means that food that is sterilized will not grow contamination unless it is exposed to it in some form. Sterilization is a process whereby all microorganisms as well as spores are completely destroyed, thereby preventing future contamination. There is a similar process we are more familiar with, called pasteurization. Pasteurization is a process that kills bacteria by heating for a predetermined amount of time. This process however, does not eliminate spores or viruses, hence isn’t as thorough for our purposes. Sterilization thus presents us with the perfect solution to preventing contamination in food.

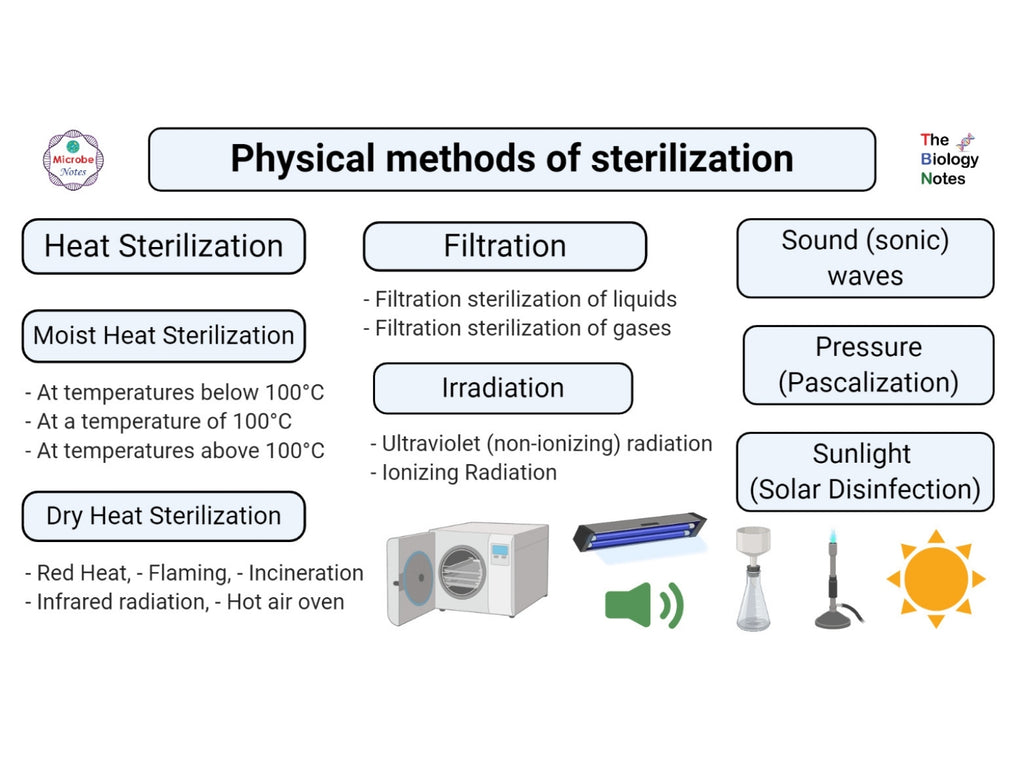

Image Source: https://microbenotes.com/physical-methods-of-sterilization/

Methods of sterilization

Sterilization can be carried out on packaged foods as well as whole foods, and can be further classified into physical and chemical sterilization. Since chemical sterilization works using additives, it is not a useful technique when it comes to food processing. There are a few different ways in which physical sterilization can be carried out, such as in the form of heat sterilization, high pressure sterilization or cold sterilization.

Heat sterilization works, as the name suggests, by the application of heat. This is one of the simplest and most widely used methods, however, it does cause thermal degradation in food. For instance, in spices such as turmeric powder or black pepper that contain volatile oils and other nutrients, heat causes these oils to evaporate, hence this technique is often unsuitable when the nutritional content of food needs to be retained.

High pressure sterilization is a technique that works by exposing packaged food to a high level of hydrostatic pressure for a few minutes. This is a safe process that does not significantly alter food, however it has its limitations, in that it does not work very effectively on dry food items such as spices and dry fruits.

This leaves us with cold pasteurization, also known as irradiation. This technique works by exposing packaged food to the energy from Gamma rays, which then render all the microorganisms present inactive. This is a quick and efficient process that does not affect the quality of the food in any significant way. Neither the packaging nor the food within is radioactive in the slightest, however, all the microbes, including spores and pathogens are effectively destroyed.

"Cold pasteurized food retains its nutritional value, while achieving 99% microbial free purity."

Is cold pasteurization safe?

The very mention of the word radiation has us running scared, but gamma radiation is just a term used for the energy that an atom releases as it decomposes. The atoms of some elements such as Uranium and Plutonium release so much energy that the result is known as an atomic bomb, however, other elements such as cobalt release only enough energy to deactivate microbes and pathogens. These are the kind of isotopes used during gamma sterilization, and the efficiency of this method renders it as one of the best when it comes to the packaged food industry. Cold pasteurization or gamma irradiation is a process that has been approved by organizations such as the WHO and the CDC, and has been in use for over three decades, in the packaged food industry.

“Cold pasteurization ensures that the food you eat is at least 99% microbial free, yet nutritious and healthy.”

Recognizing that the food we eat needs to be nutritious in every way, yet be pure, free of contamination of any form is vital. Thanks to techniques such as cold pasteurization, this has become a possibility that not only ensures 99.99% microbial free purity, but also increases the shelf life of food products significantly. With the aid of such technologies, the food we eat can and should be made infinitely healthier.